Why Robots Struggle To Produce Nike Shoes: A Technological Deep Dive

Table of Contents

The Complexity of Shoe Manufacturing

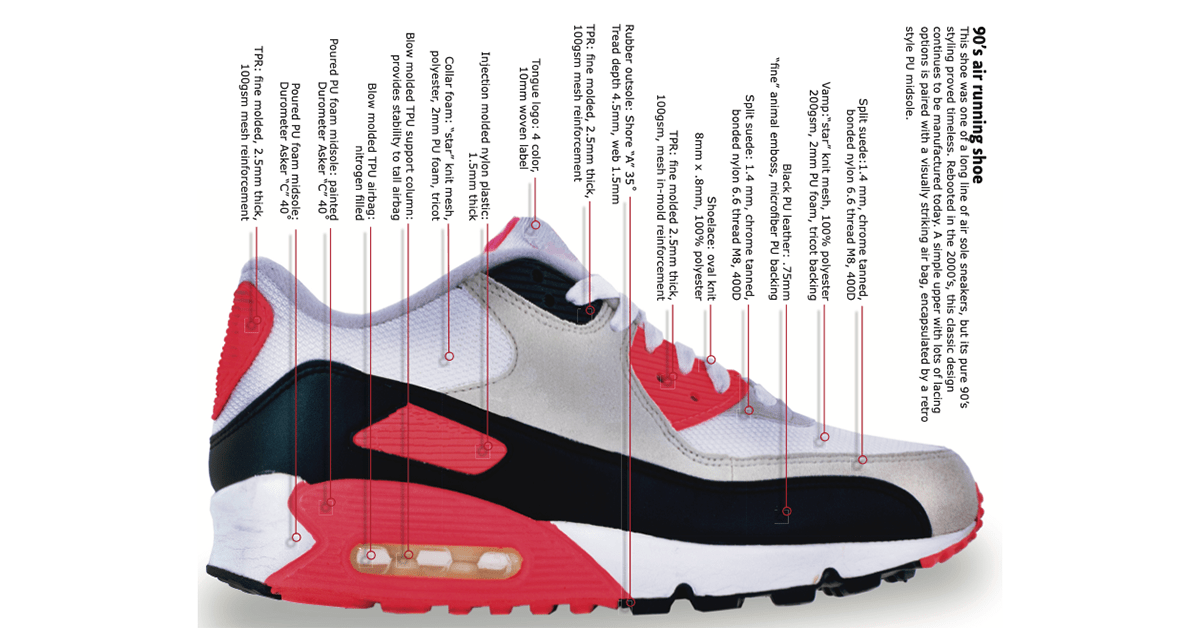

The production of a Nike shoe is far more intricate than one might initially assume. It's a multi-stage process requiring a high degree of dexterity, precision, and adaptability – qualities that currently outstrip the capabilities of even the most advanced robots.

Dexterity and Precision

Robots lack the fine motor skills and dexterity required for many crucial steps in shoe production. Consider the intricate stitching patterns found on many Nike designs, the precise placement of adhesives for optimal durability, or the careful handling of delicate materials like premium leather. Human hands possess a level of tactile feedback and adaptability that robots currently lack.

- Complex stitching patterns: These often require adjustments based on the material's texture and thickness, a level of adaptability currently beyond robotic capabilities.

- Precise glue application: The amount and placement of adhesive are crucial for the shoe's structural integrity and comfort. Inconsistent application can lead to defects and compromised durability.

- Handling varied materials: Nike shoes utilize a wide range of materials—leather, synthetics, textiles—each with unique properties requiring specialized handling. Robots struggle with the variability in these materials' textures, thicknesses, and sensitivities.

Variability in Materials and Processes

Nike's commitment to innovation means a constant influx of new materials and designs. This variability poses a significant challenge for robotic automation. Robots excel in repetitive tasks with consistent inputs, but shoe manufacturing demands flexibility and adaptability.

- Different materials, different adhesives and pressures: The type of adhesive and the pressure required for application vary significantly depending on the material. Robots struggle to adapt to this variability in real-time.

- Variations in leather texture: This affects stitching and cutting processes. Slight imperfections or variations in thickness require manual adjustments that robots currently cannot make.

- Adapting to new materials and designs: Integrating new materials and designs into automated robotic systems is time-consuming and expensive, requiring extensive reprogramming and testing.

The Limitations of Current Robotic Technology

While robotics has made significant strides, several key technological limitations hinder the complete automation of Nike shoe production.

Artificial Intelligence and Machine Learning Gaps

Current AI and ML technologies, despite their rapid advancements, are still not sophisticated enough to handle the unpredictable nature of shoe manufacturing. The vast range of tasks, the variability in materials, and the need for real-time adjustments pose significant challenges.

- AI needs massive datasets for effective training: Training robots to handle the diverse tasks involved requires immense amounts of data, which is costly and time-consuming to acquire.

- Unexpected variations in materials can confound AI systems: Slight inconsistencies in material properties can lead to errors in robotic processing, highlighting the need for robust error-handling capabilities.

- Real-time adaptability is crucial and lacking in current AI: Robots need to adapt in real-time to unforeseen circumstances, a skill that current AI systems are still developing.

Cost and Return on Investment

The cost of implementing and maintaining the advanced robotics necessary for complete shoe automation is currently prohibitive. The high initial investment, along with ongoing maintenance and potential downtime, raises questions about the return on investment.

- High initial investment in robotic systems: The cost of purchasing, installing, and integrating sophisticated robotic systems is significant.

- Ongoing maintenance and programming costs: Robots require regular maintenance, programming updates, and skilled technicians, adding to the overall cost.

- Potential for downtime due to malfunction: Mechanical failures or software glitches can lead to costly downtime, impacting production efficiency.

The Human Element in Shoe Production

Despite advancements in robotics, the human element remains crucial in Nike shoe production. Certain tasks simply cannot be replicated by machines.

Creativity and Problem Solving

Human workers possess creativity and problem-solving skills that are invaluable in shoe manufacturing. They can adapt to unexpected problems and inconsistencies in the manufacturing process, ensuring a smooth workflow.

- Quick problem-solving in unexpected situations: Humans can quickly identify and resolve unexpected issues that might halt robotic processes.

- Adapting to minor variations in materials and designs: Human workers can make adjustments on the fly to account for subtle variations in materials or designs.

- Passing on knowledge and expertise to other workers: Experienced workers possess valuable knowledge and skills that are essential for maintaining quality and efficiency.

Quality Control and Inspection

Human inspectors play a vital role in ensuring the quality of Nike shoes. They can identify subtle flaws and defects that robots often miss, using their visual and tactile skills to maintain high standards.

- Human visual inspection is more thorough than robotic systems: Humans can detect subtle imperfections and inconsistencies that automated systems might overlook.

- Detecting subtle defects and inconsistencies: Experienced inspectors can identify subtle defects that could impact the shoe's performance and durability.

- Ensuring consistency in quality across large-scale production: Human oversight is crucial for maintaining consistent quality across large-scale manufacturing operations.

Conclusion

While robots play an increasing role in various aspects of manufacturing, fully automating Nike shoe production remains a significant technological hurdle. The complexity of shoemaking, limitations of current robotic technology, and the irreplaceable human element in quality control and problem-solving all contribute to this challenge. Further advancements in AI, robotics, and materials science will be required before robots can truly compete with human workers in the production of high-quality Nike shoes. Continue to follow advancements in robots producing Nike shoes to witness the future of athletic footwear manufacturing.

Featured Posts

-

500 Million Bread Price Fixing Settlement Canadian Hearing Set For May

Apr 22, 2025

500 Million Bread Price Fixing Settlement Canadian Hearing Set For May

Apr 22, 2025 -

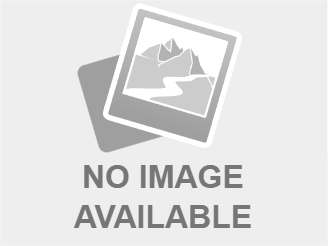

E Bay Listings For Banned Chemicals Section 230 Protection Challenged

Apr 22, 2025

E Bay Listings For Banned Chemicals Section 230 Protection Challenged

Apr 22, 2025 -

The Growing Pressure To Break Up Google Antitrust Concerns And The Future

Apr 22, 2025

The Growing Pressure To Break Up Google Antitrust Concerns And The Future

Apr 22, 2025 -

Hegseths Leaked Military Plans Signal Chats Reveal Family Involvement

Apr 22, 2025

Hegseths Leaked Military Plans Signal Chats Reveal Family Involvement

Apr 22, 2025 -

Managing Deportees Return To South Sudan A Coordinated Approach With The Us

Apr 22, 2025

Managing Deportees Return To South Sudan A Coordinated Approach With The Us

Apr 22, 2025