Overcoming The Challenges: Automating Nike Sneaker Manufacturing

Table of Contents

Technological Hurdles in Automating Sneaker Production

Automating the intricate process of sneaker manufacturing poses considerable technological challenges. The creation of a Nike sneaker involves numerous complex steps, from cutting and stitching to gluing and assembling various components. Replicating these processes with robots requires exceptional precision and adaptability. Current automation technology faces limitations in handling the variability inherent in materials and designs.

-

The Dexterity Dilemma: Robots need the dexterity and adaptability to handle a wide range of materials (leather, textiles, synthetics) and diverse sneaker designs, from minimalist running shoes to elaborate basketball boots. Achieving this level of dexterity requires advanced robotics and AI-driven control systems.

-

AI-Powered Quality Control: Integrating Artificial Intelligence (AI) is crucial for real-time quality control and adjustments to optimize the production process. AI algorithms can analyze images and data to identify defects and inconsistencies, ensuring consistent quality across large-scale production.

-

3D Printing Limitations: While 3D printing offers exciting possibilities for customized sneaker production, its current limitations hinder its widespread use in mass manufacturing. The speed and cost-effectiveness of 3D printing need significant improvement to compete with traditional manufacturing methods for high-volume Nike sneaker production.

-

High Initial Investment: Implementing advanced automation systems requires substantial upfront investment in robotics, AI software, and sophisticated infrastructure. This high initial cost can be a significant barrier for companies considering automation.

Supply Chain Integration and Logistics

Automating Nike sneaker manufacturing doesn't just impact the factory floor; it has cascading effects across the entire supply chain, from sourcing raw materials to distributing the finished products. Seamless integration of automated systems across different stages of production is crucial for realizing the full benefits of automation.

-

Integrated Automation: Success depends on the seamless integration of automated systems across different stages, from automated cutting and stitching to automated packaging and shipping. This requires careful planning and coordination between different departments and suppliers.

-

Automated Warehousing and Logistics: Optimizing material flow and inventory management is essential. Automated warehousing and logistics systems can drastically reduce lead times and improve efficiency, ensuring timely delivery of raw materials and finished goods.

-

Global Supply Chain Management: Nike's global supply chain introduces complexity. Automating such a vast network requires sophisticated software solutions for tracking, managing, and coordinating the flow of materials and information across international borders. This also involves mitigating potential disruptions from geopolitical events or natural disasters.

-

Data Analytics for Efficiency: Data analytics plays a vital role in improving supply chain visibility and efficiency. By analyzing data from different points in the supply chain, Nike can identify bottlenecks, optimize logistics, and predict potential disruptions.

Sustainability and Ethical Considerations in Automated Manufacturing

The automation of Nike sneaker manufacturing presents both opportunities and challenges regarding sustainability and ethical sourcing. While automation can contribute to a more environmentally friendly production process, careful planning is crucial to avoid unintended negative consequences.

-

Reduced Waste and Energy Consumption: Automation can minimize waste by optimizing material usage and reducing energy consumption through precise control of manufacturing processes.

-

Ethical Sourcing and Traceability: Automated systems can enhance traceability by tracking materials from their origin to the finished product, ensuring ethical sourcing and compliance with labor standards.

-

Addressing Job Displacement: The implementation of automation necessitates careful consideration of potential job displacement. Retraining and upskilling programs are essential to prepare workers for new roles in the automated manufacturing environment.

-

Sustainable Materials and Circular Economy: Automation can facilitate the integration of recycled materials and biodegradable components into sneaker production, supporting a circular economy and reducing the environmental footprint.

Overcoming the Challenges: Innovative Solutions

Nike and other companies are actively pursuing innovative solutions to overcome the challenges of automating sneaker manufacturing. The focus is on collaborative robots, flexible automation, and advanced software solutions.

-

Collaborative Robots (Cobots): Cobots are increasingly used for tasks requiring human-robot collaboration, combining the precision of robots with the adaptability and problem-solving skills of human workers.

-

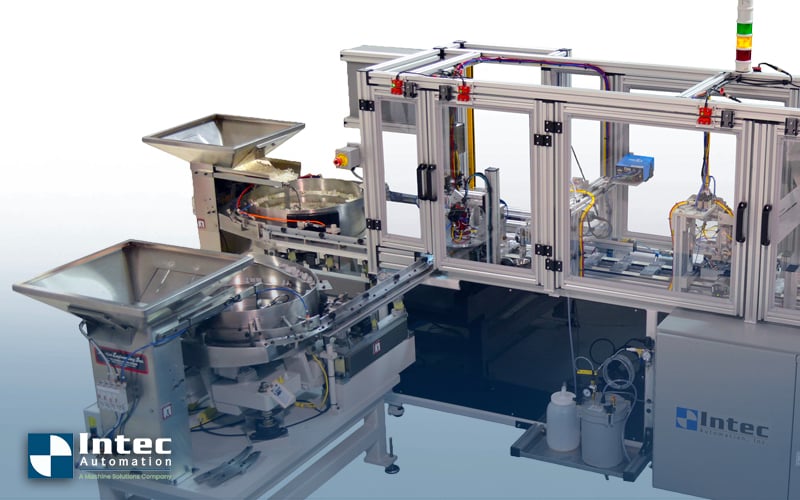

Flexible Automation Systems: Modular and adaptable automation systems allow manufacturers to quickly reconfigure production lines to accommodate different sneaker models and styles, maximizing flexibility and efficiency.

-

Advanced Software Solutions: Sophisticated software solutions are essential for managing data, optimizing production processes, and coordinating the entire manufacturing operation. This includes real-time monitoring, predictive maintenance, and inventory control.

-

R&D Investment: Continued investment in research and development is crucial to further advance automation technologies specifically designed for the complexities of footwear manufacturing.

Conclusion

Automating Nike sneaker manufacturing holds immense potential for increased efficiency, cost reduction, and enhanced sustainability. However, technological hurdles, complex supply chain integration, and ethical considerations present significant challenges. Innovative solutions, including collaborative robots, flexible automation systems, and advanced software, are vital for overcoming these barriers and unlocking the full potential of automated Nike sneaker manufacturing. The future of Nike sneaker manufacturing depends on successfully navigating these challenges through continued investment in automation and groundbreaking technologies. Let's explore the potential of automation to revolutionize the footwear industry and learn more about the latest advancements in automated Nike sneaker manufacturing.

Featured Posts

-

Cassidy Hutchinson To Publish Memoir Detailing Jan 6 Events

Apr 22, 2025

Cassidy Hutchinson To Publish Memoir Detailing Jan 6 Events

Apr 22, 2025 -

Comparing The Public Reactions To Blue Origins And Katy Perrys Recent Setbacks

Apr 22, 2025

Comparing The Public Reactions To Blue Origins And Katy Perrys Recent Setbacks

Apr 22, 2025 -

Pneumonia Claims Life Of Pope Francis At 88

Apr 22, 2025

Pneumonia Claims Life Of Pope Francis At 88

Apr 22, 2025 -

Ftc Launches Probe Into Open Ai A Deep Dive Into The Investigation

Apr 22, 2025

Ftc Launches Probe Into Open Ai A Deep Dive Into The Investigation

Apr 22, 2025 -

Trump Administration To Slash Another 1 Billion In Harvard Funding

Apr 22, 2025

Trump Administration To Slash Another 1 Billion In Harvard Funding

Apr 22, 2025